With Wayne at the helm since 1985, and a dedicated core management team, Mitchell Water Australia has progressed to become one of Australia’s largest dedicated pipeline engineering and construction companies.

Our expansion with new capabilities and a broader geographic footprint has positioned us as a major player in the construction of water and CSG infrastructure.

To meet this challenge requires an ongoing commitment to innovation to stay ahead of the competition and deliver cost-effectiveness to our customers. This is achieved without reducing the quality of construction works and most importantly the safety of our employees and the environment. Our strength is in the quality of our people and our genuine relationships with clients, partners, and communities. Our continuing growth and success are linked to our ability to deliver certainty for our clients through consistent performance and innovation.

Wayne Mitchell takes over as Director.

Mitchell patented the newly developed bedding and padding system which allows excavated material to be re-directed from the trencher via a conveyor to a self-contained screening box that is towed in the trench. The material is then screened and sieved to a selected particle size and metered out to a selected depth as bedding material.

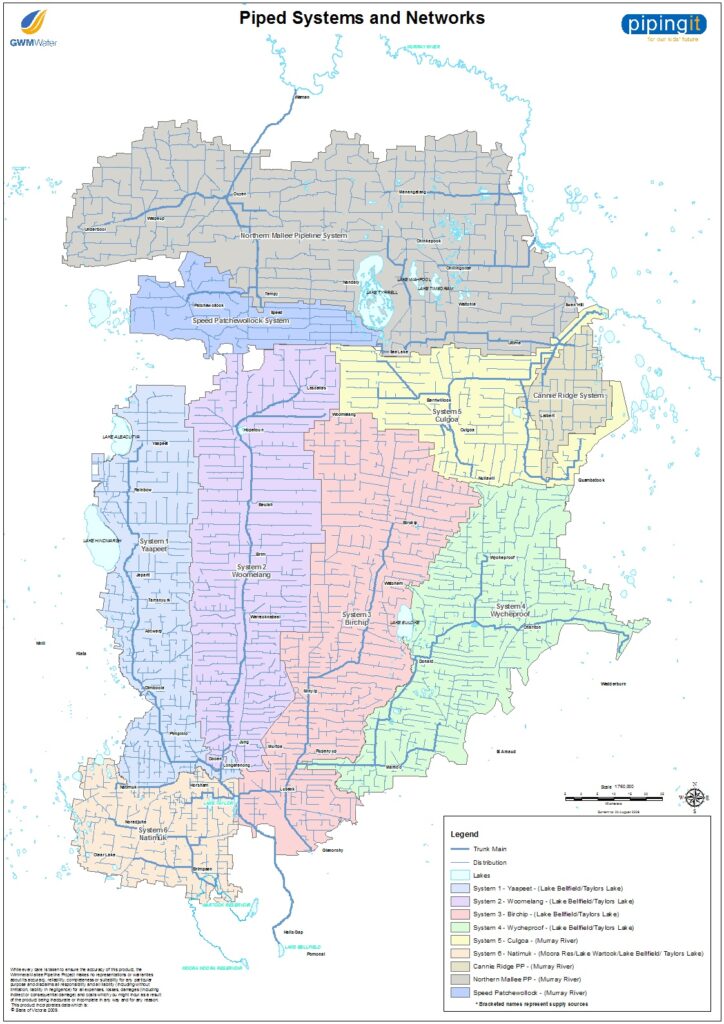

Mitchell were awarded Supply Systems 1,2,3,4,6 & 7 of the $688m Wimmera Mallee Pipeline Project (WMPP). The projects totaled 8,000km of pipelines (100km Bulk Water Transfer main DN1000 to DN700, 1,200km of Trunk pipelines DN450 to DN200 and 6,700km of Distribution pipelines DN200 to DN50), 27 Pump Stations, 28 water storage tanks, 12 earthen storages and 80 major crossings, making it to date Australia’s largest pipeline network and covering some 10% of Victoria.

The “BulletPlow” is designed, engineered, patented and put straight to work on the Wimmera Mallee Pipeline Project. The Vibratory Plough is the secret to swift pipeline construction. This plant was proven highly successful on the WMPP, installing hundreds of kilometres of pipeline in record speeds.

The Mitchell patented PE Welding Barges join the ever-growing Plant fleet, providing greater safety to our Operators, better quality welds and a cleaner finished product whilst achieving a higher production rate as the pipe gets laid directly into the trench as soon as it’s welded.